Weihs Research Group (Internship/Research)

My work in the Weihs Group, a laboratory in the Materials Science and Engineering Department at JHU, consisted of researching magnesium (Mg) alloys with the ultimate goal of developing biodegradable Mg orthopedic implants. Most of my time in the lab was spent working with Sreenivas Raguraman, while I also completed some work with Beril Ulugun.

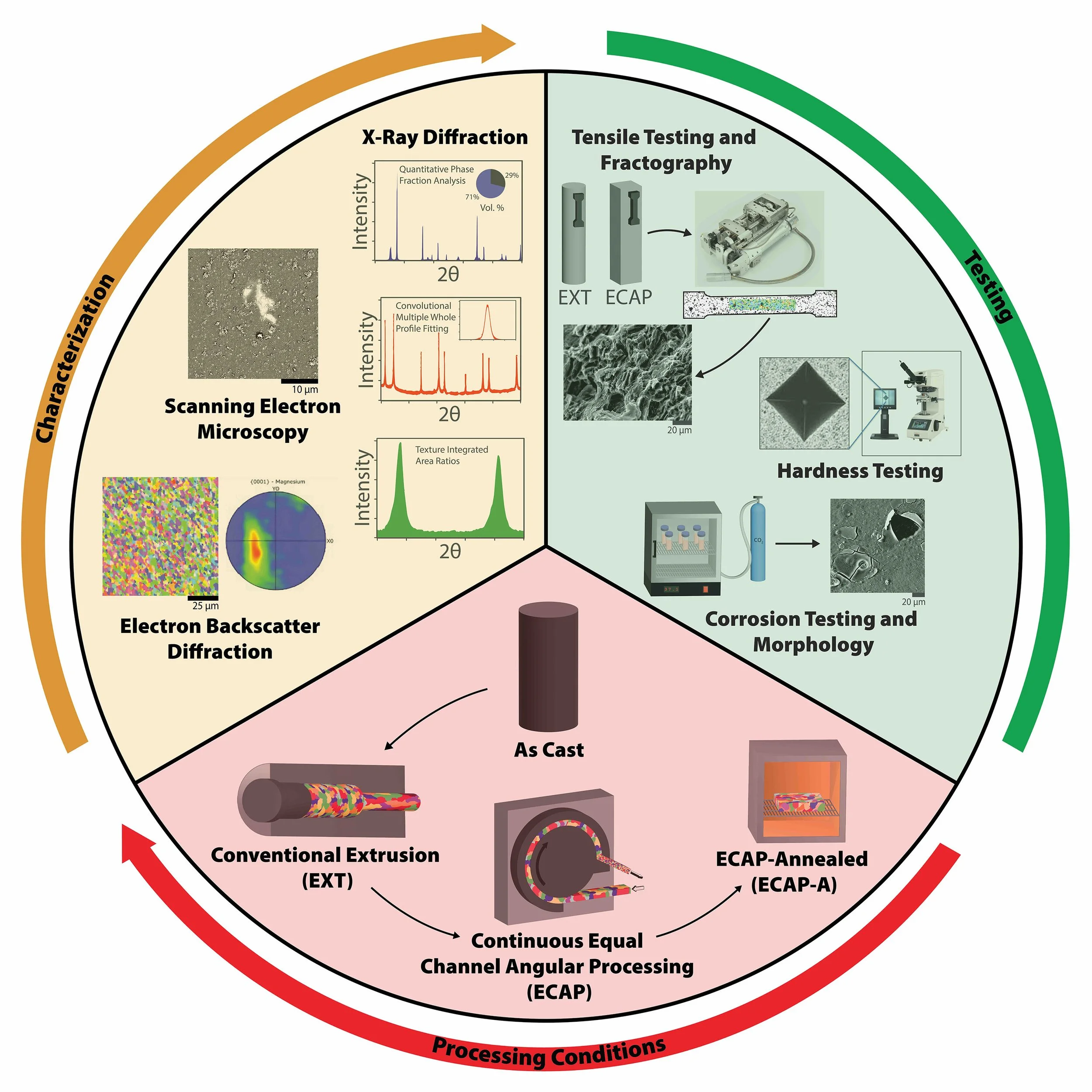

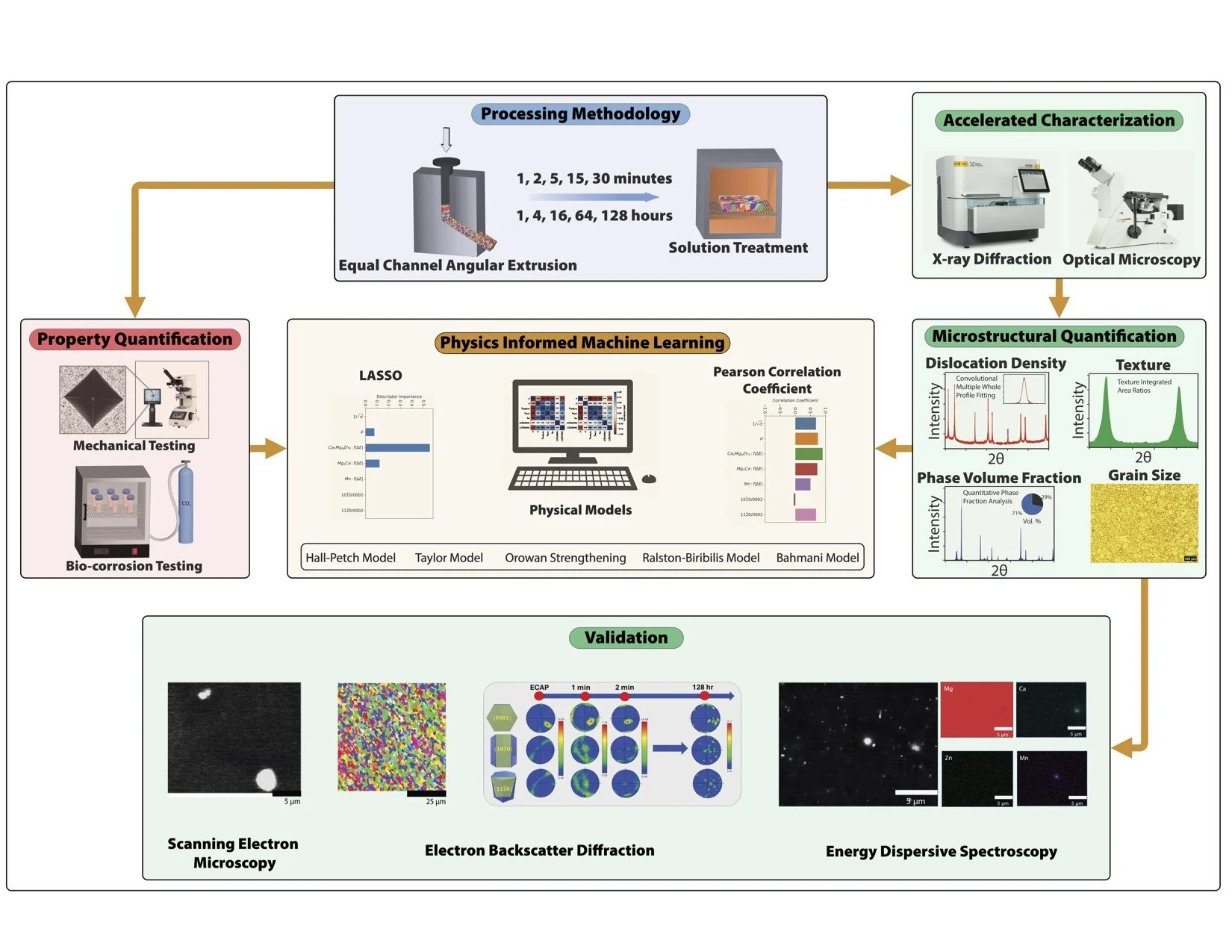

I spent much of my time on material processing, testing, and characterization work. I worked with Mg samples subjected to multiple different thermo-mechanical processing conditions, some of which I performed, including conventional extrusion, equal channel angular extrusion, solution treatment, annealing, and cold rolling. Throughout my time in the lab, I studied samples from dozens of combinations of these processing methods. To evaluate the properties of these samples, I conducted tests including immersion corrosion tests (in solutions like Earle’s Balanced Salt Solution (EBSS), Dulbecco’s Modified Eagle Medium (DMEM), and Hanks’ Balanced Salt Solution (HBSS)) and tensile tests (specifically, micro-tensile tests). I was also exposed to characterization methods like scanning electron microscopy (SEM) and micro computed tomography (micro-CT) to analyze Mg samples. The results of this testing and characterization work often went towards understanding the impact of these processing methods on the material’s mechanical properties and microstructure and towards determining the conditions that lead to optimal material properties. Some of this work and the resulting data are being used in a machine learning study in which processing-property relationship predictions are generated and experimentally tested against, after which the new experimental results are fed back into the model to continue the cycle. This generates an increasingly accurate prediction model and material processing strategies that result in favorable material properties.

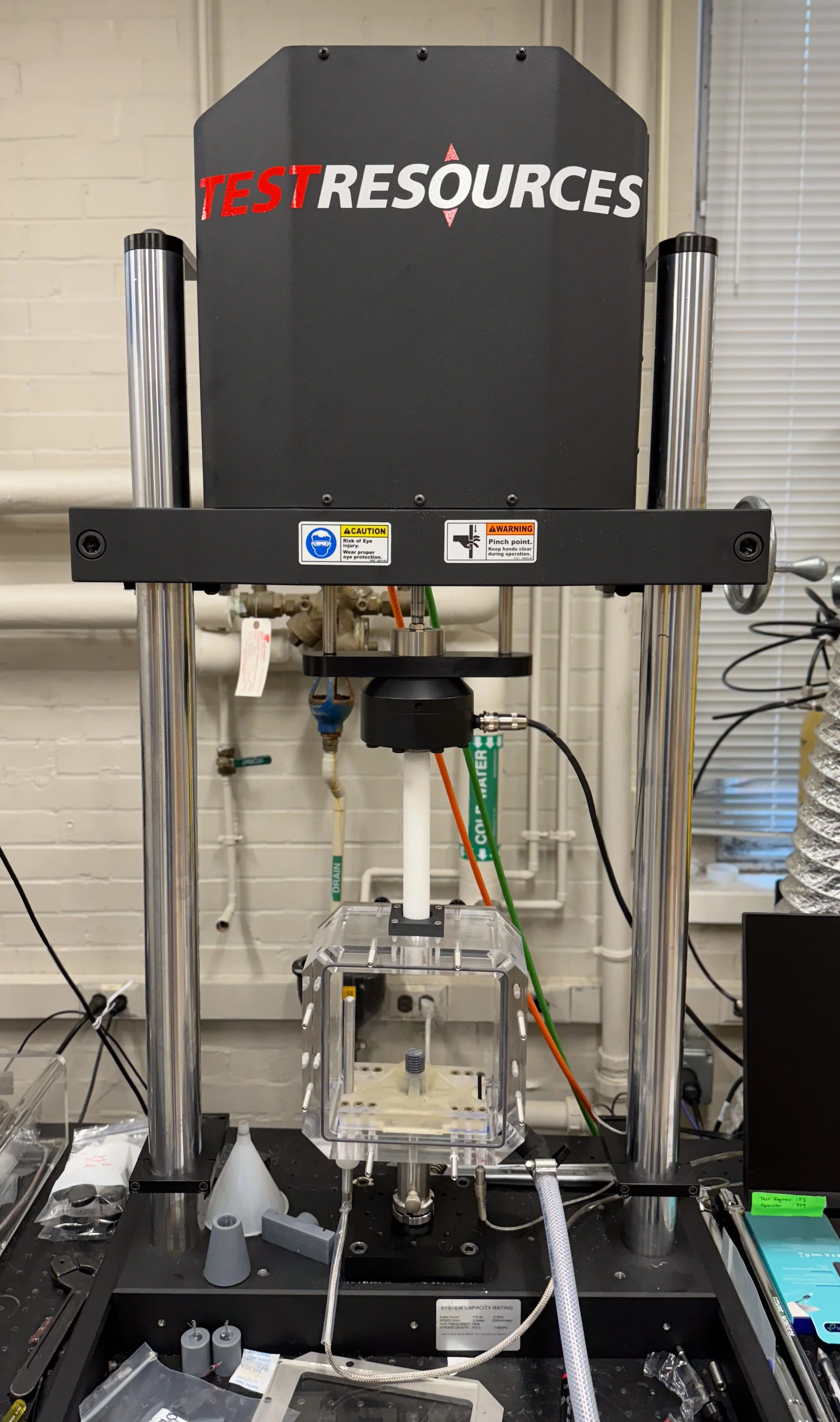

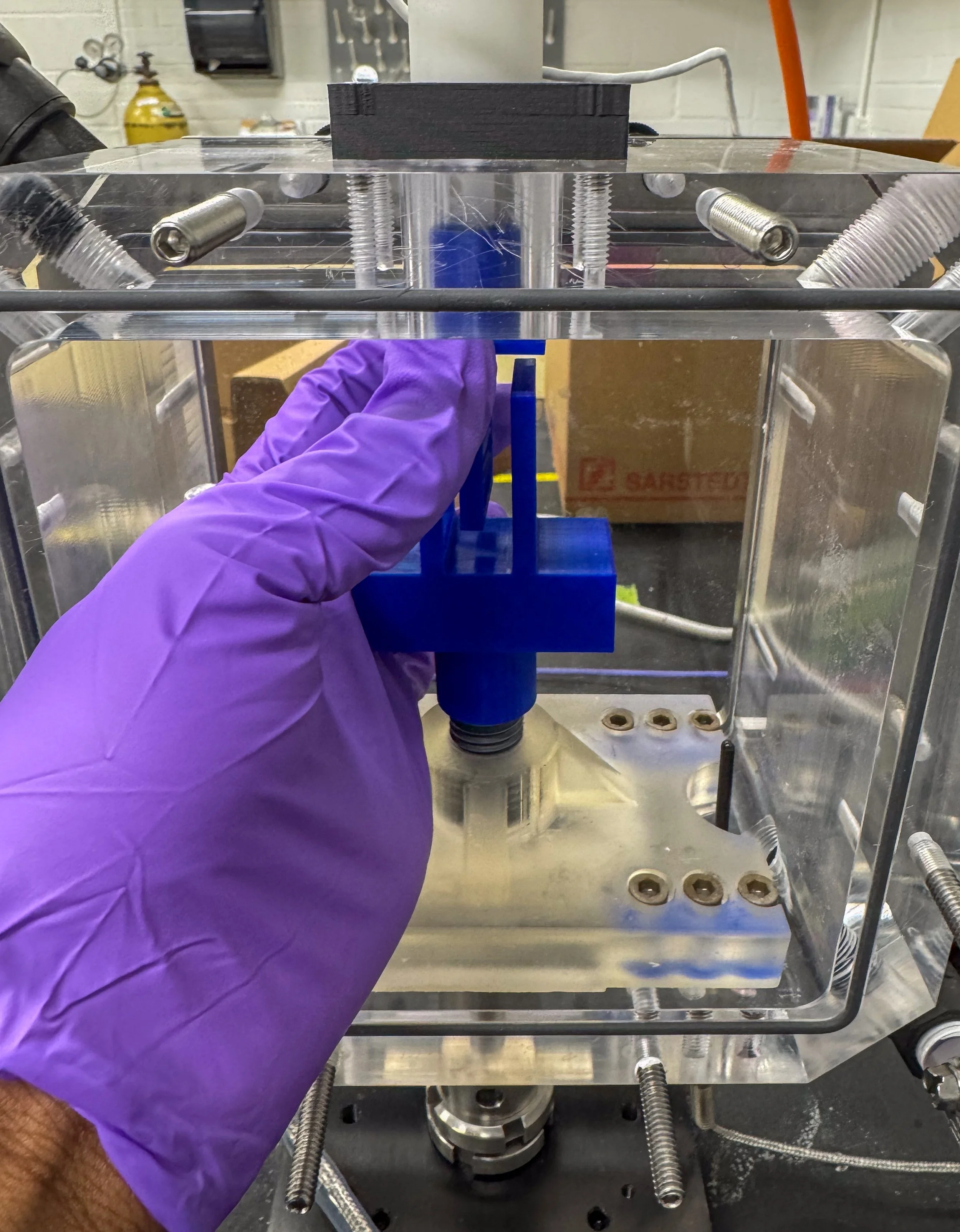

Towards the end of my time in the group, I began research into and development of an in vitro corrosion-fatigue testing system for Mg alloys (for which a standard methodology does not exist) to more accurately simulate bodily conditions. This was made possible with a custom tabletop fatigue test machine, fitted with a chamber in which corrosion solution could be added. I designed and 3D printed fatigue test grips (traditional metal grips can’t be used in the corrosive environment) and implemented a CO2 buffering and pH monitoring system, based off of an aquarium CO2 system, for the corrosion chamber in the corrosion-fatigue test system.

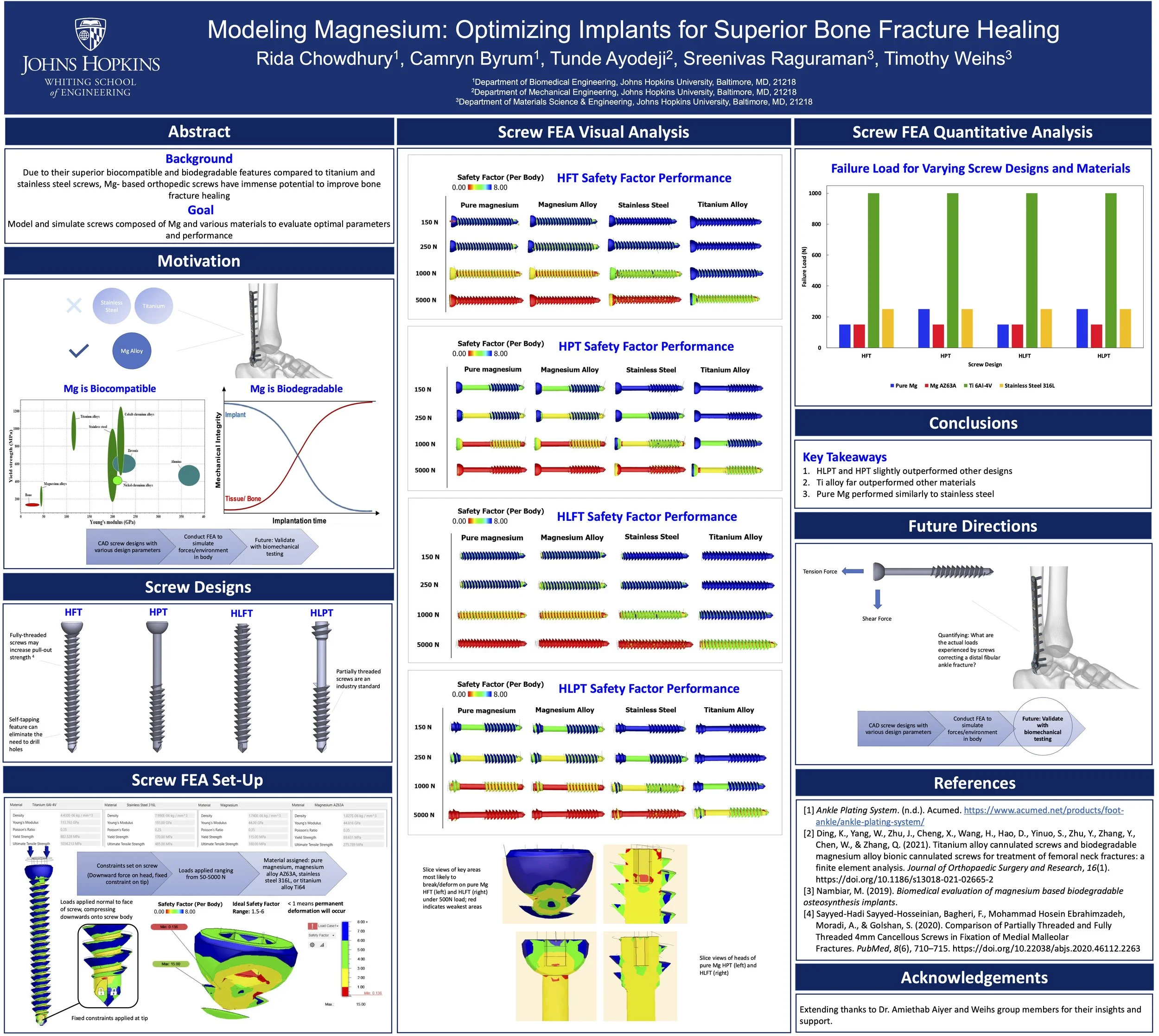

Early on in my time in the lab, I designed and analyzed implant screws simulated as Mg to get a sense of how an Mg alloy implant would perform in the body. I designed the screws in SolidWorks following standard industry designs, and finite element analysis (FEA) was then performed on each screw design, the results of which were compared analyses of screws made from traditional materials like stainless steel and titanium.

I also created multiple 3D figures and graphical abstracts, primarily in Adobe Illustrator, used in many of the lab’s presentations and publications. Some of my posters and figures are shown below, and my publications are linked here.